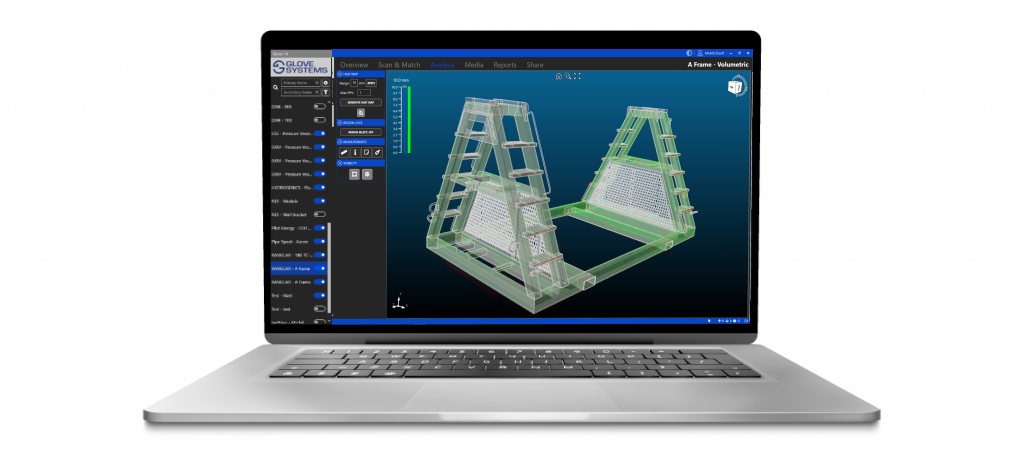

MORE ACCURATE THAN A TAPE MEASURE

Use advanced 3D laser scanning for reliable and accurate measurement

AS EASY AS USING A TAPE MEASURE

Glove Fit is designed for your craftspeople on the shop floor

NO SURPRISES FOR YOUR CUSTOMERS

Share all the information (3d pictures, photos, and reports) before shipping an assembly to avoid surprises and client issues

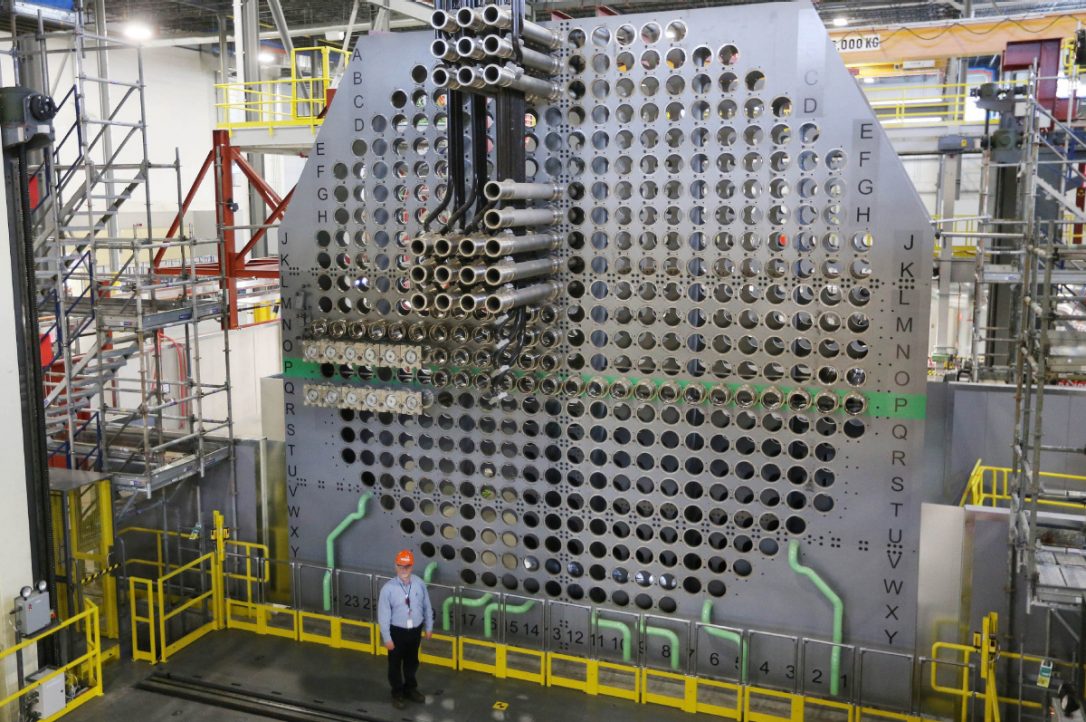

NO MORE BACK CHARGES

Avoid back charges by having an accurate and precise record of your quality product

EARN TRUST AND WIN MORE BUSINESS

Share up-to-date and accurate quality control information with your customers to gain your customer's trust and an advantage over your competitors

PROOF OF QUALITY FOR YOUR SHOP

All information (3D pictures, photos, and reports) is stored in the Microsoft's secure cloud for you forever

Increase Your Quality

Spot deviations and reduce rework costs on fabricated assemblies with highly detailed 3D dimensional measurements stored and shared in the Cloud.

:

Why Choose Glove Systems?

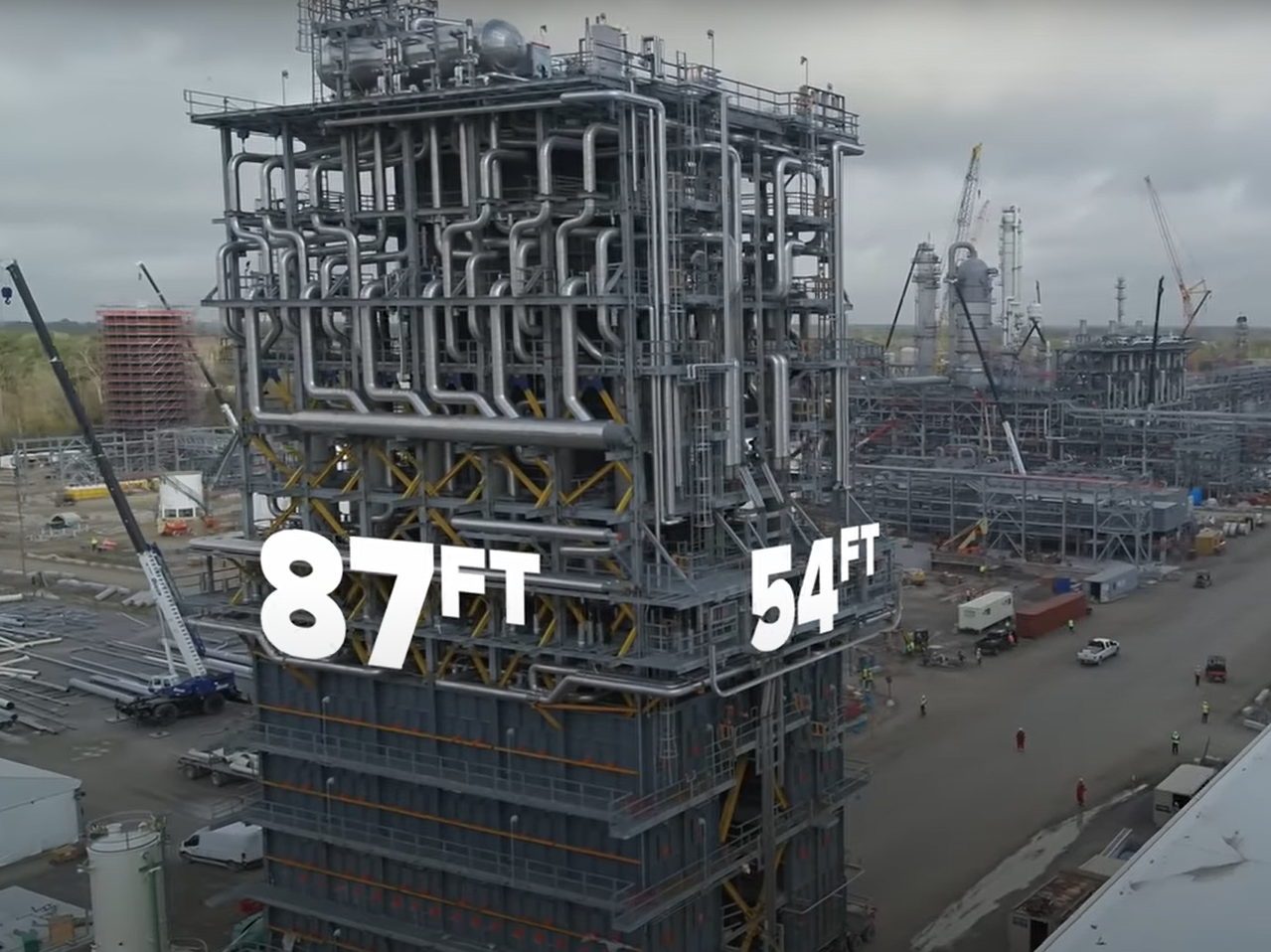

Build To Spec

Consistently accurate & shareable measurements.

Catch mistakes before they become costly.

Increase QA & QC Capacity

Accurately inspect complex components, assemblies, and modules - reduce rework.

Increase your volume, speed, and confidence.

Better Risk Management

Glove increases supply chain visibility, reducing claims and litigation costs.

Sign off on work in 3D before shipping.

Glove Systems QA/QC Platform