Glove Products

Glove Parts

Glove Fit

Glove Document

Glove Nuclear

Glove Fit

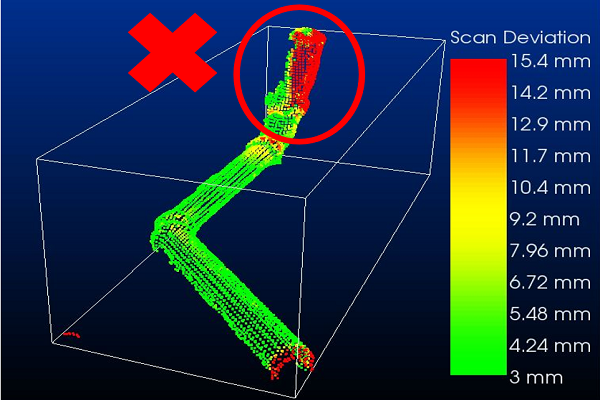

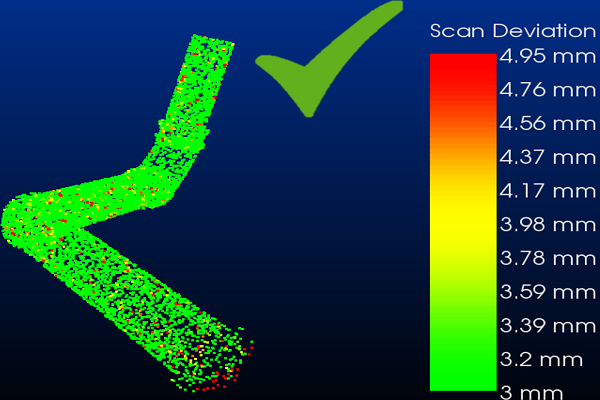

Glove Fit allows you to check work in 3D and easily catch errors.

1

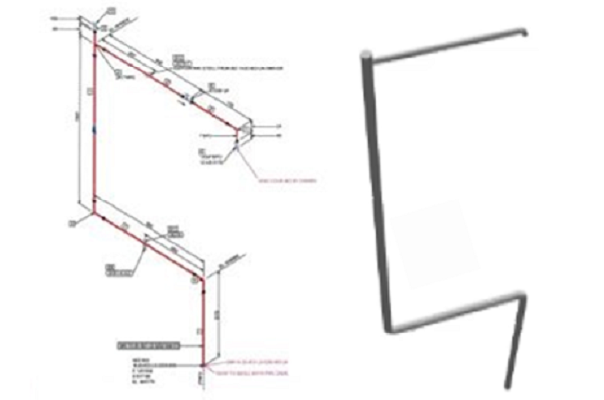

Leverage Your 3D Models - Save Time On Design Interpretation

2

Scan Your assembly Using A Glove Workstation.

3

Identify Discrepancies With 3D Visualization.

4

Store A Dimensionally Accurate Digital Twin.

The Digital Twin is stored in the cloud and can be shared with clients.

More accurate than a tape measure. All measurements are stored in the cloud.

Objective measurments. The use of tape measures can be subjective within certain tolerances.

3D visualization and feedback for rapid understanding.

Glove Parts

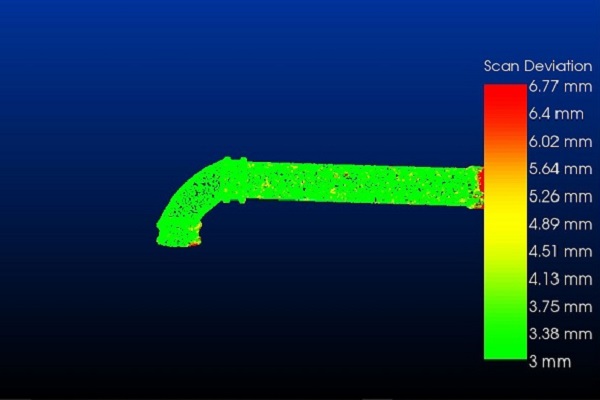

You can quickly inspect components and document any non-compliance from Glove’s database.

1

Components Arrive.

2

Scan Parts.

3

Use Glove's Database To Review For Compliance.

4

Accept Or Flag.

If a component is flagged, share a digital 3D copy of the error with supplier.

Glove’s database has over 1000 3D models of pre-built parts you can compare against.

Glove Document

Use a digital twin of your project to avoid claims and litigation.

1

Complete Your Assembly.

2

Scan Final Product and Create Digital Twin.

3

Review For Compliance.

4

Reject Non-Compliant Assemblies Before Shipping.

Glove Documents can be shared across stakeholders and the supply chain.

Access a scan, model, and digital twin of your projects in one centralized place.