Glove Project

Glove Systems for project owners

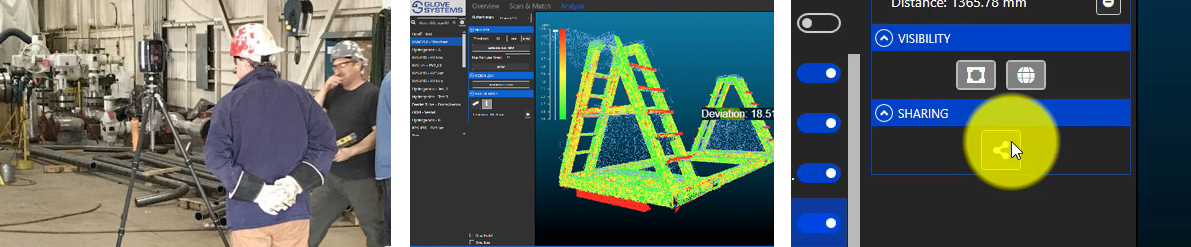

Increase visibility into your supply chain and save project costs and time by enabling remote QA/QC. Glove Systems’ 3D measurement platform creates a digital twin of your assemblies, allowing you to see accurate 3D representations of as-built assemblies, view detailed measurements, quickly spot deviations between as-built and as-designed, verify termination points and virtually collaborate with project teams to remediate on the fly.

Reduce rework costs and project risk by eliminating the need for on-site physical inspection.

Benefits to Project Owners

- Reduce rework costs and project risk by eliminating the need for on-site physical inspection.

- Keep a record of all your project’s fabrications in your own Glove secure cloud.

- Collaborate with your fabricators using your assembly/module 3D design, dimensional digital twin, heat map comparison, and photos and reports. All available to your project team in your own secure cloud.

What Project Owners Get

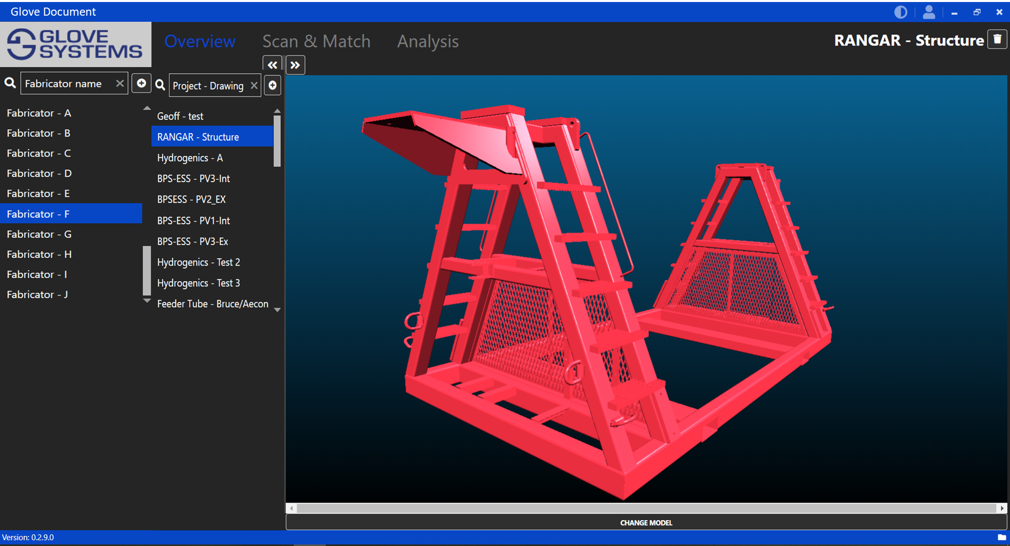

Access the Digital Twin

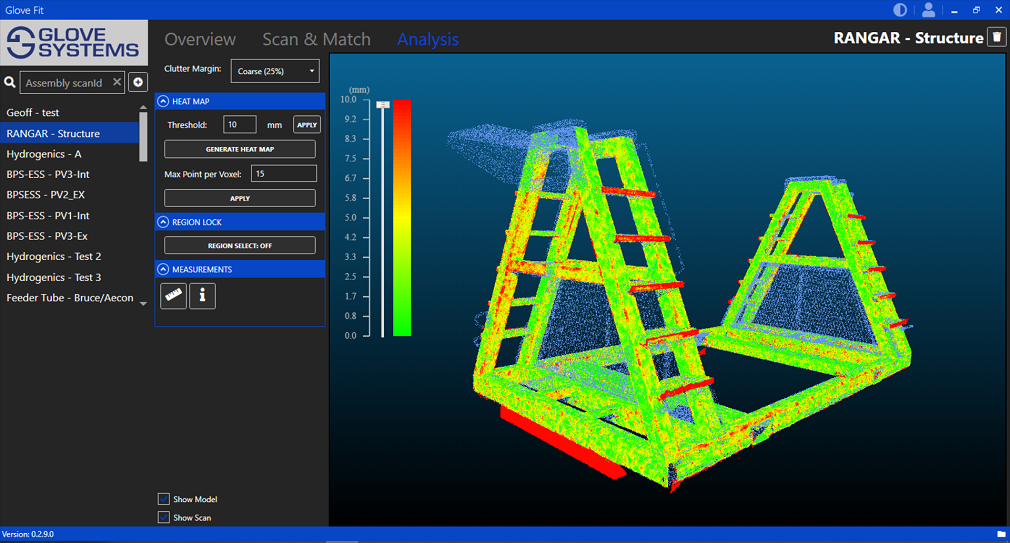

Across your fabricators, you can see the Digital Twin of each project. The Digital Twin has the information of the 3D model, acquired scans, and the heatmap analysis.

You can make additional measurements on your Digital Twin

Make Additional Measurements

When an assembly is shared, you can review the heatmap, change the tolerance and make new measurements on the point cloud. You can reject assemblies that are not to spec before they are shipped

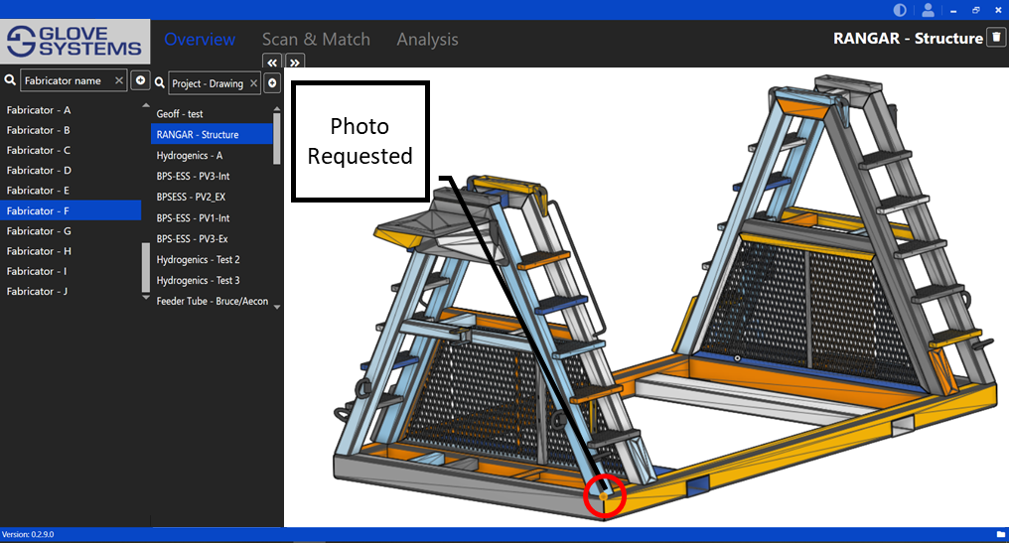

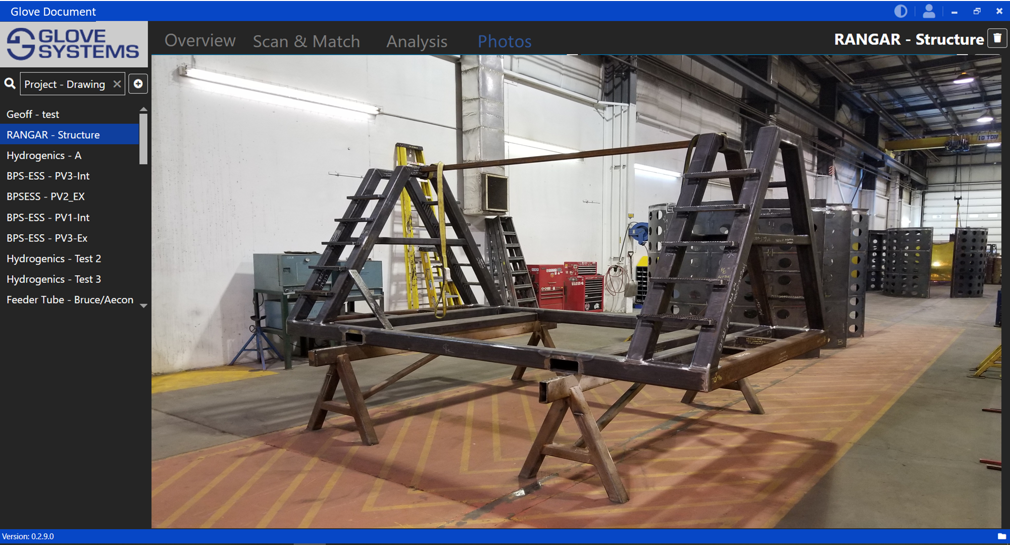

Review Photos

You can review photos of assemblies and welds.

Request photos