Nuclear Refurbishment

Complex Piping

Termination Point Measurement and Verification

Background:

The word “Termination Point” is often used in fabrication shops and modular and pre-fabrication projects. Termination points are points of connection between assemblies.

Problem:

The most critical issue when shipping and building assemblies is to make sure that the termination points are within tolerance, and everything in between has secondary importance. The current methods for measuring termination points are using laser trackers or adjustable 3D jigs. Both methods are expensive and are complex for fabrication shop workers to operate.

Solution:

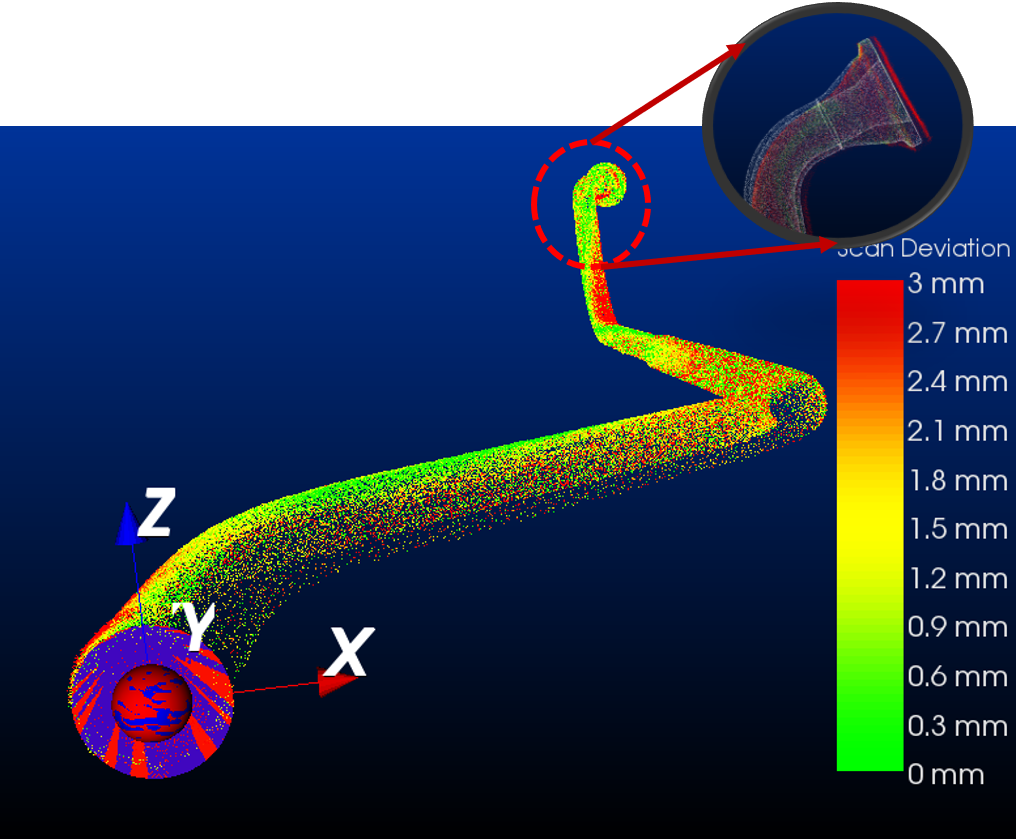

Glove Systems has solved this problem with its “Termination Checker” module. The module allows the users to accurately find the termination points on their as-builts and compare them against the model. Glove Systems’ method was demonstrated for the fabrication of feeder tubes to determine compliance of termination points. The accuracy of the method was also benchmarked against industrially accepted methods. It was found that Glove Systems method has an average accuracy of 1.03 mm.

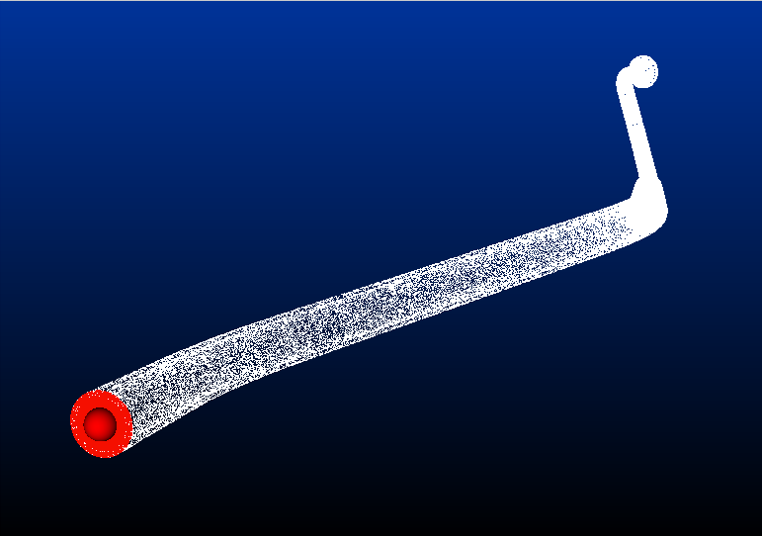

Termination Point Detected on the Model

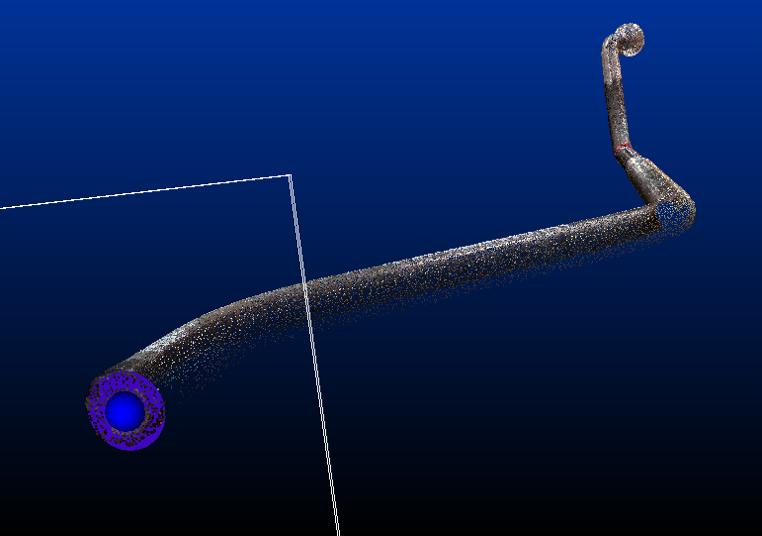

Termination Point Detected on The Scan Point Cloud

Final Termination Point Analysis