Replacing Brownfield Assets Using Measurements by Glove Systems

A Tasty Task

A food processing company (the Customer) needs to replace one of their huge storage tanks. These tanks are large, made of

expensive stainless steel, and housed inside a confined building adjacent to the main plant, where they used raw materials in

the manufacturing process. The tanks are old, one is leaking fluid, and is now beyond the point where simple repairs or

maintenance can bring it back to productive capacity. The company has some old engineering shop diagrams about the tank

configuration, fittings, flanges, and footings.

The tank is at height and is attached via connector piping directly through the exterior wall of the building. The company cannot

easily retrofit the fittings or the input/output pipe due to the placement and cost. Ideally, the new tank is an exact replica of the

existing one. The replacement is also time-sensitive: the company cannot afford for the tank to be offline for too long, or to

fail—without it, the plant does not function, and there is no feasible alternative. As the plant employs a few thousand staff, an

unplanned shutdown is very costly.

The Customer contracted with Alps Welding as the Fabricator to measure the old tank, design the replica, procure the steel,

contract any subcomponents, build the replacement, and install the replacement at the plant. Initially, Alps intended to rely on

the original design documents of the old tank to build the replica. If the measurements were incorrect, or the diagrams were

inaccurate, then the replica would not fit in the place of the old tank, fittings may be off, and the plant connection would be at

risk. The consequences to the Fabricator and the plant were high—a possible two-day downtime to correct the replica.

Objectives

1. Build an exact replica of the asset

2. Minimize rework and waste

3. Complete rebuild within time and budget constraints

Results

1. Limited engineering time

2. Constraints of resources and build time

3. Accuracy is impeded; cannot rely on documentation

4. Asset is 15 feet off the ground; difficult to reach

5. Factory needs to be in operation

6. Limited acceptable downtime

The Solution

The Fabricator used Glove Fit (Glove Software) to scan the existing tank, capture its design in digital format, and validate the

fabricated replica with the original tank.

Reflective sensors were applied to the tank to calibrate the scanner, which then generated an exact digital version of the tank (a

technique called point cloud) into Glove Fit, an easy-to-use point-cloud measurement program by Glove. This process required

less than 2 hours of time.

The point cloud is precise, complete, and highly accurate. The Fabricator then used their normal design software to plan the

fabrication, with the point cloud informing their work. The 3D model was effectively built from this digital version of the original

asset itself, eliminating the risk of the shop diagrams being faulty or inaccurate. The process saved engineering, measuring, and

drafting time.

In this case, the scan and Glove Fit revealed a surprising feature on the tank—a nozzle had been added to the tank at some point but not reflected in the shop

diagrams. The nozzle was at height and would have been easily overlooked by a conventional measurement team working on ladders and scaffolding.

As the fabricated asset took shape in the shop, its various elements were repeatedly compared to the point cloud to ensure strict alignment with the original tank.

The model’s accuracy eliminated the risk of rework and remediation at the site. The risk to the Customer, of a potential unplanned multi-day downtime event, was avoided.

Figure 1. (a) Initial design model. (b) The completed site scan of the tank. (c)

The scan-vs-3D-model reveals a missed nozzle at the back. The blue object is

the 3D design model’s point cloud and the gray object is the scan point cloud.

(d) The missed nozzle was detected, and the design model was updated

accordingly. (e) The tank to be replaced and the back nozzle. (f) Top view of the

tank (to be replaced). (g) Top view of the tank( to be replaced).

Impact Analysis

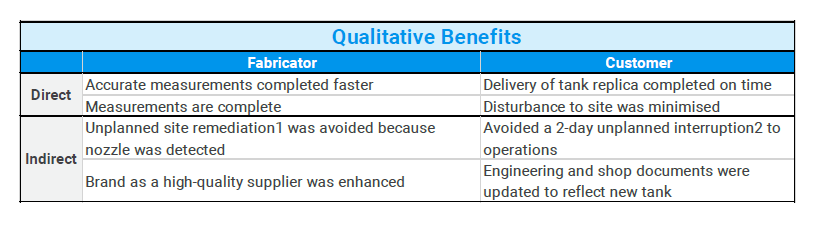

A review of this scenario reveals the qualitative and quantitative benefits to the Fabricator and the Customer, summarized in

Table – Qualitative Impacts.

1 Without an exact replica of the original tank delivered to the site, the Fabricator would be obliged to dispatch 2 workers at the

prevailing hourly rate to the factory to remediate the replica, a task lasting up to 1 day, at a cost ranging from $1,600 to $2,000

(2 workers * $100/hour * 8-10 hours). Additional fabrication materials (steel parts) would be shipped as well for an incremental

cost of $3000. The Fabricator typically absorbs this cost. To replace this loss to the business, the Fabricator needs to find the

equivalent in margin through incremental sales, or $100,000 in new sales (5% margin).

2 The factory avoids 1-2 days of reduced production capacity.

Conclusions

Glove Systems helped both Alps Welding and the Customer avoid

significant costs. Errors are reduced through using LIDAR technology,

eliminating drawing or measurement error. The Fabricator’s reputation

benefitted from the fast turnaround and accurate work. The Customer

avoided an unplanned shutdown of their business. The Customer also

now possesses correct engineering documents.